|

LATEST ISSUE Profile Show Preview Ask the Expert Technology Association Assembly Management CALENDAR February 12-14 March 19 March 20-21 April 8 April 22-24 June 18-20 June 18-20

For Email Marketing you can trust

Copyright 2010 Peterson Publications, Inc.

|

Cold Gas Plasma Surface Modification - Optimize Plastics Bonding Adhesion by Scott R. Sabreen, The Sabreen Group, Inc. Technology Feature January-February2010 Polymeric and elastomeric substrates often can be extremely challenging to achieve robust bonding adhesion strength to like or dissimilar materials. Bonding applications are not limited to only adhesives, but include printing inks, paints and coatings, encapsulant and potting compounds, metallization and more. This article describes "Low Pressure Cold Gas Plasma" surface modification as one type of process that can resolve many three-dimensional bonding problems through plasma chemical surface activation and functionalization. The science of well known "atmospheric or air" surface modification processes will be compared. Particularly notorious tough-to-bond substrates include silicone and rubber elastomers and engineering thermoplastics including acetals, fluropolymers, polyolefins, nylons, polycarbonates, polyesters, styrenics, and more. The underlying reasons why many plastics and elastomers are difficult to bond are that they are hydrophobic non-polar materials, chemically inert, and possess poor surface wettability (i.e., low surface energy). What Is Plasma? Cold Gas Plasma Surface Modification It is the response of the highly reactive species generated with the polymers placed in the plasma field, on inner conductive electrode aluminum shelves or cage, breaking molecular bonds that results in chemical/physical surface modifications without affecting the bulk substrate properties. Cold gas plasma process modifies non-wettable hydrophobic surfaces to bondable hydrophilic wettable surfaces via chemical and physical mechanisms. See Diagram 1. Micro nano-scale roughened surfaces can be selectively altered in the plasma environment either by a bombarding effect of ions accelerated toward the surface, or by a chemical etch process. Roughened surfaces have higher surface areas (peaks and valleys), equating to a higher number of binding sites that improve bonding adhesion. See Diagram 2. Unique to the cold gas plasma is that it successfully can pretreat PTFE. Further, polymer coatings can be grown on surfaces through a process called plasma-enhanced chemical vapor deposition (PECVD). Coatings are highly conformal with thickness (≈2µ) dependant on process time. Examples of coatings include SiO2-like and Diamond-like. A key application is to coat the insides of plastic and glass tubes and containers with a quartz-like material that acts as a barrier to leachables and prevents breakage1.

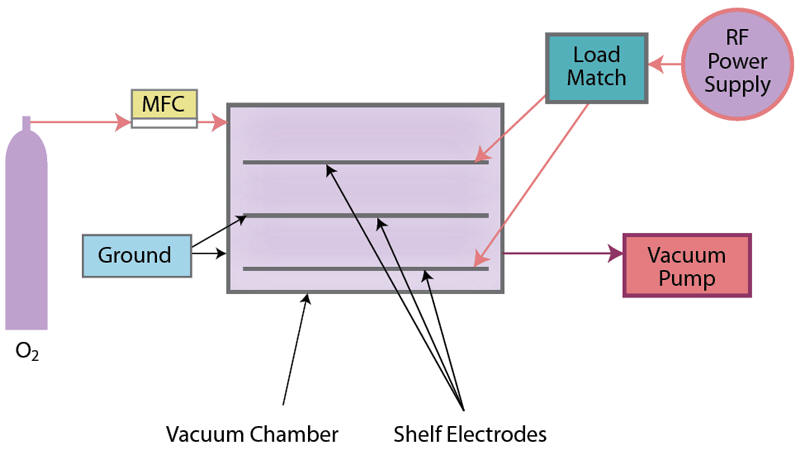

Diagram 2. Surface roughening by kinetically knocking contaminants from the surface, increasing surface area topography Equipment System Set-Up The parts to be cleaned are simply placed on the inner electrodes which are removable shelves or a cage. The parts/shelves subsequently are loaded into the reaction chamber in which the process begins by first pumping down to a vacuum. The process gas then may flow through the system at a regulated pressure while pumping continues. The RF generator supplies excitation power. At the end of the plasma process the closed vacuum chamber returns to ambient pressure, whereby the treated parts are removed and ready for bonding. Most systems allow for automatic control of process variables including (typically) pressure, power, gas flow, temperature, and cycle times (intermediary stage and total elapsed time). See Diagram 3.

Diagram 3. Cold Gas Plasma Schematic Processing Control Parameters Misnomers of Cold Gas Plasma Pretreatment Gas-Phase Surface Oxidation Pretreatments Atmospheric Surface Modification Systems Flame Plasma Treatment uses the highly reactive species present in the combustion of air and hydrocarbon gas (to create the plasma). Flame treatment is exothermic; however, heat does not create the chemical functionality and improved surface wetting. Flaming will clean dirt, debris, and some hydrocarbons from the substrate. Flaming will not remove silicones, mold releases, and slip agents. Flame treatment can impart higher wetting, oxidation, and shelf-life than electrical pretreatments due to its relative shallower depth of treatment from the surface, 5-10nm. Ozone is not produced2. Classical Electrical Corona Discharge is obtained using a generator and electrode(s) connected to a high voltage source, a counter electrode at potential zero, and a dielectric used as a barrier. That is, high frequency-high voltage discharge (step up transformer) creating a potential difference between two points requiring earth ground 35+kV and 20-25kHz. This pretreatment process has virtually no cleaning capabilities. Ozone (NOx) is produced. Electrical "Air Plasma" is Corona discharge spot treatment (also termed blown air plasma/forced air corona/blown arc). This treatment head consists of two hook electrodes in close proximity to each other connected to a high voltage transformer generating an electric arc of approximately 7-12 kV, lower frequency 50-60 cycles/sec (relative to electrical corona discharge). Then using forced air, a continuous electric arc produces a corona discharge, "plasma." No positive ground needed. This pretreatment process has virtually no cleaning capabilities. Ozone is produced. Electrical Blown ion plasma also is termed Focused Corona plasma/Potential-free plasma. This treatment utilizes a single narrow nozzle electrode, powered by an electrical generator and step-up transformer and high pressurized air in which an intense focused plasma is generated within the treatment head and streams outward. Since the process is potential-free, it can be used to pretreat conductive products. This pretreatment process can clean dirt, debris, and some hydrocarbons from the substrate but not most silicones and slip agents. New research indicates that fine etching of the surface can create new topographies for increased mechanical bonding. Ozone is not a byproduct. UV radiation/Ozone pretreatment and chemical primers also are performed at atmospheric conditions. These pretreatment methods will be discussed in a future article. Factors Influencing Adhesion and Aging Plasma-treated surfaces age at different rates and to varying extents relative to factors with the surrounding environment. Aging characteristics and their storage shelf-life are essential to manufacturing process operations. Activated surfaces may have a shelf-life of hours, days, months, or longer. The cold gas plasma process demonstrates significantly extended activation lifetimes3 and more uniform treatment compared to atmospheric methods4. It is recommended to bond, coat, paint, or decorate products as soon as possible following pretreatment. The global need to achieve robust bonding adhesion on plastic and elastomeric products demands surface modification "activation" pretreatments. Chemical and physical functionality and surface roughening, via gas phase surface oxidation processes, can resolve most adhesion problems. Each method can be application-specific and may possess unique advantages and/or limitations. Plasma-oxidized surfaces can deleteriously affect downstream assembly processes, such as poor heat sealing/welding, when overtreatment occurs. While cold gas plasma is the most expensive method, in some applications it has the capability to yield the most robust results. Atmospheric treatments are lower cost. However in some cases, day-to-day humidity variation can affect the treatment uniformity. Careful evaluation of all process factors and an understanding of the alternative surface modification technologies are important. References: 1. Demetrius Chrysostomou, PVATepla, March 2009 2. Scott R. Sabreen, Joe Digiacomo, Plastics Decorating Magazine 3. Edward M. Liston, GaSonics International, Journal of Adhesion 1988 4. Dori & Kushner, University of Illinois and 3M Scott R. Sabreen is founder and president of The Sabreen Group, Inc. (TSG). TSG is a global engineering company specializing in secondary plastics manufacturing processes – surface pretreatments, bonding, decorating and finishing, laser marking, and product security. For more information, call (888) SABREEN or visit www.sabreen.com or www.plasticslasermarking.com. |

|||||||||||||||