|

LATEST ISSUE Profile Show Preview Ask the Expert Technology Association Assembly Management CALENDAR February 12-14 March 19 March 20-21 April 8 April 22-24 June 18-20 June 18-20

For Email Marketing you can trust

Copyright 2010 Peterson Publications, Inc.

|

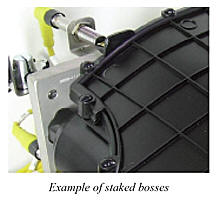

The InfraStake Process - Seeing the Light by Scott Beute, Extol, Inc. Assembly Update July-August2008 The practice of forming a molded stud or boss in order to retain another component is nothing new. Long ago, engineers recognized the benefits of eliminating glue, screws, and other fasteners, and as a result, they developed several different methods of heat staking that have been around for quite some time.

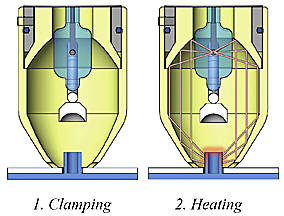

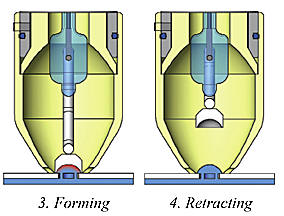

Conventional Staking Several established methods for staking plastic parts exist. These methods typically can be used for any type of thermoplastic. Some of the more common materials that are staked include polyethylene, polypropylene, ABS, polycarbonate, acetal, and polyamide. The process also works with plastics that contain fillers such as glass or talc. The traditional methods include hot air staking, thermal staking (heated punch), and ultrasonic staking. Although these processes all melt and form plastic, they each have some weaknesses when it comes to minimizing cycle time and producing parts with acceptable joint strength. Some of the weaknesses are poor part clamping, stress-induced show surface marking opposite the stud (ultrasonics), high operating costs, danger to machine operators, plastic stringing or sticking to the punches, and process variation. The struggle to overcome these weaknesses ultimately led to the development of the InfraStake process. Process Overview The InfraStake process can be broken down into four basic steps: Clamping, Heating, Forming, and Retracting. Clamping Industry experts have recently discovered that plastic parts are not always known for their dimensional stability. One of the first challenges when staking plastic parts together is making certain that they are properly assembled. Because actual parts donít always match the CAD models, an assembly process that can compensate for some part variation (warp) can be a real advantage. The InfraStake process clamps the parts together at each stake point, ensuring that they are firmly pressed together throughout the entire cycle. This completely eliminates the need for secondary clamps in most cases.

Heating The InfraStake process works with materials of all different colors and transparencies. Dark, opaque materials absorb infrared energy more quickly than light, translucent materials and typically allow faster cycle times. The energy source used is a 12-volt, 100-watt technical-grade halogen lamp, not unlike those used in many automotive fog lamps. Once the lamp is energized, a reflector directs the infrared energy from the filament into a column around the punch. This column of energy travels downward until it is focused on the full perimeter of the boss by the concentrator.

Itís Energy Efficient. The ability to focus the infrared energy precisely where it is needed also minimizes the power consumption. Unlike a typical hot-air system, which uses a 400-watt heater for each stake point, an InfraStake module uses only a 100-watt lamp. Since the price of electricity hasnít been going down recently, this has a real impact on the operating cost of the equipment. Additionally, because the system does not have any internal components that have to Ďwarm upí before use, no preheating is necessary. Finally, the system uses only a small amount of cooling air, which minimizes the amount of compressed air required. Itís a Controlled Process. The InfraStake process heats the boss uniformly until the plastic reaches a semi-molten state. The infrared energy is focused only on the portion of the boss that extends through the mating part, so there is very little chance of affecting the show surface opposite the boss. The standard round profile works well for many different boss shapes, but the reflective surface geometry also can be tailored to non-circular bosses, like blade or tab studs, if necessary. The process parameters for the heating portion of the InfraStake cycle are quite simple. The lamp is either on or off, and the amount of infrared energy transferred to the boss is determined by the amount of time that the lamp is on. The other parameter that affects the heat cycle is the cooling airflow rate. A small amount of cooling air flows through the InfraStake module during the staking cycle for several reasons. It stabilizes the temperature of the lamp and lamp holder and maintains positive pressure in the area surrounding the polished reflective surfaces. Positive pressure keeps the surfaces clean by keeping out dust, airborne contaminants, and potential out-gassing contaminants. The cooling air also helps regulate the surface temperature of the boss to prevent overheating. Finally, the airflow keeps the punch relatively cool so it can effectively remove the heat from the plastic once it makes contact with the boss. The InfraStake controllers error-proof the process by monitoring the current draw of each module during the heat cycle and alerting the operator if there is a problem. The InfraStake body has two integral tracks that accept proximity sensors triggered by the position of the punch coupler magnet. These sensors can be used to verify that a boss is present before the cycle and to verify that the punch has extended completely at the end of each cycle.

Forming

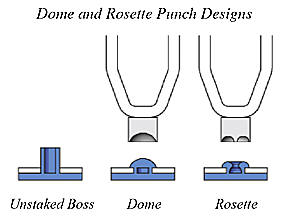

The punch cavity is designed to match the volume of plastic in the unstaked boss. This ensures that each stake is fully formed. The punch is gold-plated to reflect the infrared energy, and its location (outside of the focal point of the reflective surfaces) and the cooling airflow help it maintain a reasonable temperature so it can draw heat out of the molten plastic quickly and prevent sticking. When staking glass-filled materials, which can be abrasive, the punch detail often is machined from A2 tool steel, which is hardened to resist the abrasion.

Several different geometries can be used for the punch cavity. For round bosses, the dome style and the rosette style are quite common, and the strength is actually very comparable between the two. In fact, the diameter of the clearance hole in the mating part often affects joint strength more than the punch geometry. The dome punch design minimizes the distance that the plastic must be displaced, and the lack of a center pilot reduces its sensitivity to bosses that are slightly off-center. As a result, it often can provide a larger process window than a rosette design. Rectangular shapes also can be used if necessary when staking features such as tabs.

Retracting The final step in the InfraStake cycle is to retract the punch. Now it is important that the plastic has resolidified to the point where it can maintain its shape and structure. If it does not, the stake joint may loosen or the plastic may stick to the punch. The InfraStake concentrator functions as a stripper plate, holding the part down and preventing it from lifting as the punch retracts. The InfraStake module is only removed from the part after the punch has retracted from the staked boss. Boss Sizes

The InfraStake technology offers a flexible approach to joining plastic parts. Whether the application requires a complete machine or a package of integration components, the InfraStake process can provide unique advantages over conventional staking methods through safety, efficiency, and control. Extol, Inc., Zeeland, Mich., is a manufacturer of innovative plastics joining equipment and custom, automated assembly machinery. Extol can provide complete, turn-key production InfraStake machines ranging in size from small standard presses to large, custom machines. The company also offers a complete line of InfraStake components and controllers specifically engineered for integration. To contact Scott Beute, manager - technology and education, call (616) 748-5029 or e-mail [email protected]. To contact Bill Reed, national sales manager, call (616) 748-9955 or e-mail [email protected]. For more information on Extol, Inc., visit www.Extolinc.com. |

|||||||||||||||

Against this

backdrop, a nonconventional staking process called InfraStakeģ, a relative

newcomer in the business, is continuing to gain popularity. As the name

suggests, the energy source is infrared light, and the heat transfer mode is

radiation (the safe type). The InfraStake module clamps the parts together,

heats the boss evenly with precisely directed infrared light, and forms the

plastic with a non-heated punch driven by a low-force pneumatic cylinder.

Against this

backdrop, a nonconventional staking process called InfraStakeģ, a relative

newcomer in the business, is continuing to gain popularity. As the name

suggests, the energy source is infrared light, and the heat transfer mode is

radiation (the safe type). The InfraStake module clamps the parts together,

heats the boss evenly with precisely directed infrared light, and forms the

plastic with a non-heated punch driven by a low-force pneumatic cylinder.

Itís Safe. The

InfraStake module transfers the infrared energy from the lamp to the boss

through radiation. Because the working area is completely encapsulated, the

operator cannot access the area where the infrared energy is being focused once

the cycle has begun. Even when the operator can contact the outside of the

InfraStake module during the staking process, the surface temperature remains

safe to the touch. This is possible because the reflective surfaces are plated

with gold, which is very efficient at reflecting infrared energy. This improves

both the safety and the efficiency of the process by keeping the energy where it

is needed, and not anywhere else. Without the risk of burning the machine

operator, a simple press mechanism often can be used on machines that would

otherwise require heavy guarding, a shuttle, or a turntable for operator

protection.

Itís Safe. The

InfraStake module transfers the infrared energy from the lamp to the boss

through radiation. Because the working area is completely encapsulated, the

operator cannot access the area where the infrared energy is being focused once

the cycle has begun. Even when the operator can contact the outside of the

InfraStake module during the staking process, the surface temperature remains

safe to the touch. This is possible because the reflective surfaces are plated

with gold, which is very efficient at reflecting infrared energy. This improves

both the safety and the efficiency of the process by keeping the energy where it

is needed, and not anywhere else. Without the risk of burning the machine

operator, a simple press mechanism often can be used on machines that would

otherwise require heavy guarding, a shuttle, or a turntable for operator

protection.

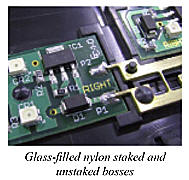

The InfraStake

process produces consistent radial heating of the boss. As a result, a

low-force, pneumatic cylinder driving the punch is sufficient to form the stud,

minimizing stress and potential part damage. This is especially advantageous for

PC board assemblies and other delicate applications.

The InfraStake

process produces consistent radial heating of the boss. As a result, a

low-force, pneumatic cylinder driving the punch is sufficient to form the stud,

minimizing stress and potential part damage. This is especially advantageous for

PC board assemblies and other delicate applications.

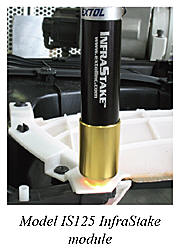

The InfraStake

process can be used to stake bosses of many different sizes. The IS125 model,

which is the most popular size, is 31mm (1.25 inches) in diameter at the

concentrator. Due to recent design improvements, it can now stake bosses up to

8mm (0.313 inch) in diameter and up to 12mm (0.5 inch) tall. There also are two

other standard modules, the IS170 and the IS230, which can stake larger bosses,

but those applications are far less common. In cases where the bosses are too

close together for standard modules to fit, custom heads also can be designed.

The InfraStake

process can be used to stake bosses of many different sizes. The IS125 model,

which is the most popular size, is 31mm (1.25 inches) in diameter at the

concentrator. Due to recent design improvements, it can now stake bosses up to

8mm (0.313 inch) in diameter and up to 12mm (0.5 inch) tall. There also are two

other standard modules, the IS170 and the IS230, which can stake larger bosses,

but those applications are far less common. In cases where the bosses are too

close together for standard modules to fit, custom heads also can be designed.