Pad Printing Tip: Remember Substrate Height

by Inkcups Now

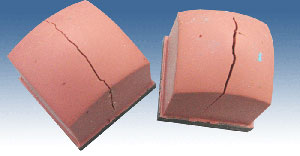

Have you ever been in the middle of a production run only to discover that the printing pad suddenly split in two? Most people would think there is something wrong with the pad itself, hoping that a new pad will do the trick. When the same problem occurs over and over, it's time to find out what’s really going on.

Does the picture look familiar? It was sent in by a customer who had no idea why his pad printing pads kept splitting. It was neither the ink nor the surface of the substrate being printing on, and the pad wasn't being handled improperly. Eventually, we determined the settings of his machines had led to a serious case of overcompression of the pad.

What happened was that he started printing on a thin substrate with the appropriate machine settings for that object. When he changed the object he was printing on to something that was taller – without adjusting the pad transfer height – it caused overcompression of the pad. By putting too much stress on the pad, it split in two.

Silicone print pads can split for other reasons too:

- The pad is simply too old and needs to be replaced.

- The use of aggressive hardeners and thinners in the ink will dry out the pad, causing it to split.