Adhesive Bonding of Polyamide (Nylon)

by Scott R. Sabreen

The Sabreen Group

Polyamide, commonly known as Nylon, is a semi-crystalline polymer. The two most common grades are Nylon 6 and Nylon 6/6. Nylons are used in thousands of automotive, aerospace, medical and industrial applications where high-temperature, solvent-proof, electrically-shielded parts are needed. While these characteristics are excellent for performance, poor surface wettability and moisture are bonding challenges for manufacturers.

Nylon polymers are inherently difficult to bond because they are hydrophobic, chemically inert and possess poor surface wettability (i.e. low surface energy). Further, nylons are hygroscopic and will absorb moisture in excess of 3 percent of its mass of water from the atmosphere. Moisture, in and of itself, creates adhesion problems. The rate of moisture absorption is dependent upon time, relative humidity and temperature. Therefore, it is important to perform bonding processes as soon as possible following molding operations, or package the parts tightly in non-poly bags with a desiccant. Proper drying procedure of nylon resins is critical to processing and part performance.

Surface Cleaning and Pretreatment

Surface preparation is critical toward achieving high adhesive bond strength. Surfaces must be clean and contamination free from dirt, grease and oils. Low molecular weight materials (LMWM) such as silicones, mold release and anti-slip agents inhibit bonding. To suitably clean nylon surfaces and remove LMWM materials, use Toluene, Xylene, Acetone or MEK (in accordance with company solvent policy and state law). Alcohol is a weak solvent and only removes superficial dirt but not hydrocarbon contaminates. Proper technique must be used at all times including using lint-free cloths and wearing powder-free hand protective gloves. Excess solvent creates weak boundary layers of un-removed chemicals leaving a haze build-up that will inhibit bonding.

Nylon bonding applications often require plasma pretreatment immediately following solvent cleaning. Gas-phase surface oxidation pretreatments for nylon include: electrical corona discharge, electrical atmospheric plasma, electrical air plasma, flame plasma and low pressure RF cold gas. These processes are characterized by their ability to generate "gas plasma", an extremely reactive gas consisting of free electrons, positive ions, and other species. Chemical surface functionalization also occurs. In the science of physics, the mechanisms in which these plasmas are generated are different but their effects on surface wettability are similar. Each method is application specific and possesses advantages and/or limitations. For example, electrical pretreatments do not remove/clean all poly-aromatic hydrocarbons so it may be necessary to continue solvent cleaning. RF Cold Gas pretreatment will remove hydrocarbons, thus pre-cleaning is not necessary.

As a general rule, acceptable bonding adhesion is achieved when the surface energy of the substrate is approximately 10 dynes/cm greater than the surface tension of the liquid or adhesive. The surface energy of untreated nylon is approximately 40 dynes/cm. Therefore, the desired post-treatment surface energy needs to be in the range of 50-54 dynes. In this situation, the liquid is said to "wet out" or adhere to the surface. A common method for measuring surface energy "wetting" is the use of calibrated dyne solutions in accordance with test method ASTM D2578.

Epoxy Adhesives & Curing

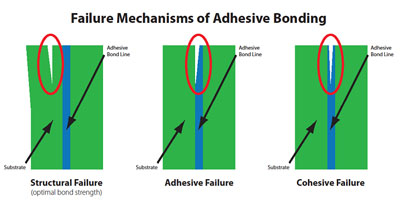

By definition, "adhesion failure" occurs at the interface between the adhesive and the adherend (substrate). Visually, there is residual adhesive remaining at any location on only one surface and not the second substrate adherend.

Optimal joint design is critical in any adhesive bonding application. Bonded joints can be subject to tensile, compressive, shear, peel or cleavage forces, often in combination. For many nylon applications, 2-component, heat curable structural epoxy adhesives are ideal. Two-component epoxy consists of mixing an epoxy resin plus a hardener, or procuring "duo-pak" applicators. Uniform, thin bond line thickness (0.002 – 0.007 inches) is preferred for optimal shear and tensile strength properties.

Full cure time is typically in the range of seven (7) days at 75°F, but is variable between applications and environmental conditions. The speed of cure can be accelerated by adding heat (120-210°F), which results in additional polymerization and can give the epoxy better properties. Bake time and temperature is application specific. One-component epoxies eliminate the need for mixing but cure only with the addition of heat (normally 250-300 °F). By comparison, the working life of two-component epoxies is limited.

A common mispractice is to apply extra adhesive to improve bond strength. Excessive adhesive is detrimental and a leading cause of bonding failures. Epoxy adhesives have relatively high coefficients of thermal expansion. Bond lines need to be kept thin and uniform in thickness (typically 3-5 mil for maximum shear strength). The adhesive supplier can provide guidance for optimal bond line thickness for your application. Pre-measured "duo-pak" applicators will eliminate mixing problems and provide a more exact mix ratio. They also provide better stoichiometric chemical reactions, resulting in better strength & outgassing properties.

Relative to the surface texture of the part to be bonded, as molded, a textured surface will increase mechanical interlocking adhesion in addition to solvent cleaning and plasma pretreatment. Texture can be accomplished within the mold tool or manually using a Scotch-Brite pad. For example, NTMA mold cavity Finish "40-Diamond buffed 1200 Grit" will likely improve bond strength versus Finish "10-Fine Diamond 8000 grit (0-3 micron range). Even slightly textured surfaces will be beneficial.

In summary, to achieve high-strength adhesion bonding of nylon and epoxy adhesives, I recommend the following:

- Ensure the nylon-66 resin is properly dried before molding.

- Conduct the bonding process as soon as possible following molding.

- Clean the part surface with an alternative solvent that will remove surface debris and hydrocarbon contaminates.

- Consider implementing a plasma surface pretreatment to increase surface wetting/chemical functionalization.

- Apply a thin, uniform adhesive bond line (optional heat cure for two-component epoxy). Additional benefits can be gained if the product has a textured surface.