Premium Metallic Graphics and Wraps Add Sparkle, Value to Products

by Laurie Weller

Roland DGA

In the world of decorated plastics, silver sells. In fact, adding metallic effects to promotional items, smart phone covers, products and accessories can greatly increase their value. Metallic graphics are typically priced 30- to 40-percent higher than traditional CMYK graphics. And they’re an easy upsell. When shown a full-color CMYK image and the same image with metallic, customers go for metallic every time.

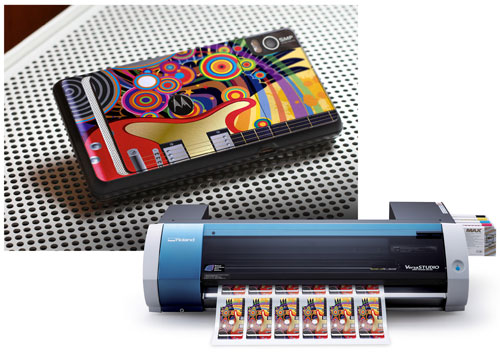

With inkjet printing technology, it’s easy to make products sparkle. Simply print a metallic label, decal or wrap and then apply the graphic to the product. This entire production process is achieved easily, on one device, with a metallic inkjet printer/cutter.

Those already in the plastics decorating business probably have most of the technology needed to support a metallic inkjet printer/cutter. Software packages such as CorelDRAW and Adobe Illustrator can be used to create the design files and now come with full support for metallic colors and effects. The printers can be purchased from manufacturers, such as Roland, with prices starting at under $8,500 for a desktop model. Investing in an integrated printer/cutter versus a print-only device is recommended. This will allow for maximum efficiency because graphics can be printed and contour cut in one seamless workflow.

When working with metallic inks, there are a number of technical factors to consider. First, it is very important to understand how the ink is circulated. Metallic ink particles are heavy – or at least heavier than CMYK ink particles – and need to stay in suspension in order to print properly. An ink circulation system handles this process automatically, circulating the ink at the right intervals to minimize waste, costs and maintenance requirements. A printer should come equipped with an effective ink circulation system.

Like other inks, metallic adheres to coated vinyl media better than uncoated substrates. Metallic ink is less scratch resistant than CMYK inks on some substrates. To improve its durability – and to create specific metallic and pearlescent hues – metallic ink typically is combined with CMYK. Roland recommends laminating the graphic as well to help make the image last even longer, especially in high traffic environments.

It is true that metallic inks are more costly than traditional CMYK inks. Typically, though, metallic ink is used sparingly – a little shimmer goes a long way. In the end, you can expect operational costs to average below 50 cents per square foot for most applications. And, as mentioned above, the higher profit margins make the investment well worthwhile. Not only will metallic graphics make products shine, they also will increase customer satisfaction and help companies build their bottom line.