Ultrasonic Welding with Automation and Robotics

by Udo Skarke

Herrmann Ultrasonics, Inc.

Flexible ultrasonic welding cells incorporating robotics eliminate the need for time consuming set-up and tool changes.

Related Link

- Click here to view a table that illustrates a selection of different weld positions in an actual production cell.

Automation processes continuously are looking for faster cycle times, tighter tolerances of the process and increased reliability. Pre-loaded ultrasonic welding units are another step to push the limits even further.

Depending on the methods of automation for mass production, flexible production of components or a combination of multiple functions, different technologies and approaches can be selected to meet the requirements. Commonly used technologies are cam-driven systems for high throughput, as well as robots that are getting more economical and creating new opportunities and areas of use.

The high processing speed that is provided by ultrasonic welding makes it very attractive for mass production, despite the higher initial investment. During the process, the ultrasonic vibrations that are generated from electrical voltage precisely melt the plastic at defined joining points and create a homogeneous bonding. Cycle times of up to 60 cycles per minute can be realized, depending on the required weld times between 80 and 450 milliseconds. The cold weld tools do not require a heat-up phase and are ready for operation at any time without the need of maintaining a certain temperature level. Good and profound preliminary application consulting is crucial though. This is particularly applicable for component design in order to achieve best-possible focusing of the ultrasonic vibrations in the joining area.

Pre-loaded ultrasonic welding systems

Pre-loading means that the cylinder already has been extended via an intelligent pneumatic system when the weld tool gets in contact with the material. Therefore, the machine immediately can start the welding process. The time saved in applications with many weld spots may be significant. The joining of acoustic foam for an engine compartment with up to 20 weld spots is an example that is more and more frequently realized by means of robots. In this case, time savings per application may amount to as many as 20 seconds.

In more detail, a pre-loaded system consists of a primary drive (cam, servo, robot, etc.) and a secondary, pneumatic drive. In the secondary drive, pressure continuously is applied to the pneumatic cylinder of the actuator. Thus, the cylinder of the actuator is in extended condition. The pressure in the cylinder corresponds to the trigger force required for the application. The actuator is in pressurized condition, which is called "pre-loaded." The primary drive moves the "pre-loaded" actuator to the weld area, lowers the sonotrode onto the plastic part to be welded to form contact with the surface and travels over the contact point of the cylinder so that the cylinder piston of the actuator is pushed back. The resulting pressure increase in the cylinder is vented via a pneumatic pressure regulator (precision pressure regulator or proportional valve) in order to keep the pressure in the cylinder at a consistent level. Subsequent to the primary travel reaching its end position, the trigger is initiated and the weld process is started. The buffered pneumatic cylinder now performs the weld stroke. The required weld force is defined by the pneumatic pressure regulator or proportional valve. After the weld (end of hold time), the entire actuator is moved back from the weld area by the primary drive. During this travel, the actuator moves back to its extended pre-loaded position and then is ready for the next weld cycle.

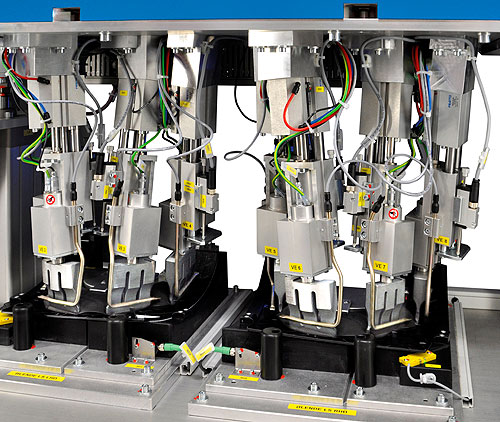

One example for the use of pre-loaded systems is for applications with very large quantities and repeated production of the same or similar plastic parts, where fast-operating automated rotary systems or linear transfer machines frequently are used. These systems operate in time-optimized cycles; they are partly cam-controlled and partly servo-controlled, with cycle times of a second or less per assembly. The paramount purpose of such production systems is to exploit the full cycle-reduction potential up to the last millisecond and thus to increase the parts output. If an ultrasonic welding process is integrated, all requirements for cycle time must be met. The ultrasonic welding process, which only takes a few milliseconds, combined with the pre-loaded concept, which drastically reduces the sonotrode up/down travel times, meets this demand with a high degree of reliability for millions of parts. In general, the actuators are mounted on a carriage, which is driven either by a cam drive or a servo-controlled direct drive (primary shaft).

Another typical setup involves automated assembly systems where the pre-loaded technology causes the primary shaft with the pneumatically pre-loaded actuator to travel towards the weld area and thus to pressurize the pneumatic drive cylinder of the actuator. The ultrasonic generator now receives an external trigger signal from the overriding machine controller (PLC). As soon as the primary shaft reaches its end position, the weld process of the ultrasonic system monitored by the HU weld process control is started: trigger process, ultrasonic welding, hold time after expiry of the hold time, the main machine controller (PLC) receives a ready signal and moves the primary shaft back to home position. While retracting, the actuator is pushed into the pre-loaded end position. If no weld process controller is available, ultrasonic start is directly triggered by the machine controller (time delayed).

Multi-head solutions

It also is possible to use several ultrasonic welding systems within automation lines; this is referred to as a multi-head application. There are specially developed ultrasonic products available for automation; the machines are available with frequencies of 20, 30 and 35kHz and with outputs of up to 6,200watt. There are very compact designs available that mostly are used for robot applications. In addition, there are new control concepts that easily can be adapted to the complexities of the various joining applications and are characterized by easy integration into the overall control architecture.

Robotics

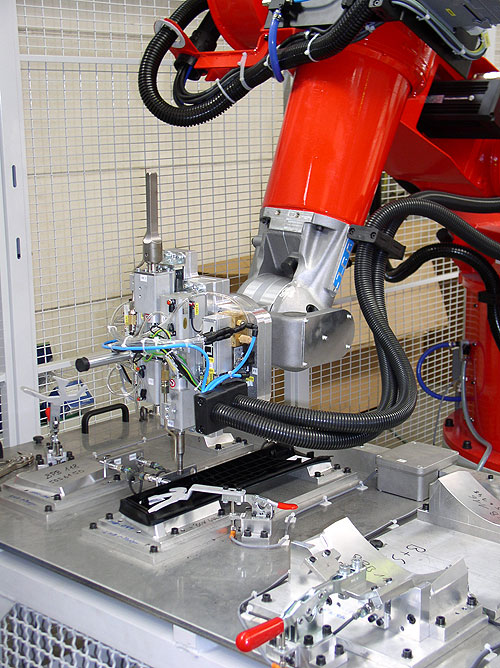

The effect of shrinking high-volume products and growing multiple versions of lower-volume products, especially in the automotive industry, have forced manufacturers to look for more flexible assembly solutions. Today's requirements include maximizing flexibility and floor space and minimizing tool change setup time. The latest developments are flexible ultrasonic welding cells incorporating robotics for the assembly of multiple plastic components. This eliminates the need for time consuming set-up and tool changes.

One of the key features of such assembly solutions is six-axis robots. This component can be supplied by any robotics manufacturer, as long as the end-of-arm load and welding forces are taken into consideration when sizing the robot.

A second key feature is the specially designed end-of-arm weld head, utilizing two different (up to four) weld sonotrodes to accommodate different welding operations without tool change.

Compact ultrasonic actuators with low weight easily can be mounted on robot arms and are thus well-suited for fast and low-energy joining of plastic parts. Pre-loading the pneumatic cylinder of the actuator saves time – up to one second per weld spot. This is particularly noticeable in applications with many weld spots.

Robots are utilized in situations where several identical weld spots must be performed on one larger plastic component. Robot cells provide the highest flexibility with very low counts and high variant variety. However, the robot performs the welds step-by-step, which requires time. With the help of the pre-loaded concept, the sonotrode up/down travel times can be reduced and productivity of the robot is increased. Despite the reduced cycle times, the weld process achieved is impeccable.

In order to ensure repeatability of the weld process, the weld distance must not only be traveled by the robot itself, but also by the actuator. Otherwise, after reaching the weld end position, the robot would have to apply home position pressure at a consistent value during hold time (ultrasonic off). However, this cannot be realized with the required degree of precision and, what is more, elaborate programming of the robot motion sequence (position control without ultrasonic) would be required. The solution is to always integrate actuators when planning automation concepts. In this way, a repeatable weld process can be ensured during the plasticization and solidification phases.

The pre-loaded technology causes the robot with the pneumatically pre-loaded ultrasonic unit to travel towards the weld area and thus to pressurize the pneumatic drive cylinder of the actuator in joining direction. The ultrasonic generator now receives an external trigger signal from the robot controller. As soon as the programmed end coordinates of the robot motion are reached, the weld process of the ultrasonic system monitored by the weld process control is started: trigger process, ultrasonic welding and hold time. After expiry of the hold time, the robot receives a ready signal and lifts the sonotrode off the component by a few millimeters, before directly moving on to the next weld spot. During the lifting phase, the actuator is retracting into the pre-loaded end position. If no weld process controller is available, ultrasonic start is directly triggered by the robot controller (time delayed).

Another important component is a CNC controller, which controls all weld processes and interfaces with the robot. A separate, optimized weld program can be established for each weld position, providing the possibility to switch between weld modes, using different forces or amplitudes and setting individual min/max weld process control windows.

The controllers are equipped with an Ethernet port, allowing interfacing directly with plant networks or off-site QC departments via the World Wide Web for remote diagnostics. This also allows users to monitor and modify weld process parameters that provide closed-loop data collection and parts tracking.