Basic Test Methods for In-Mold Labels and Label Materials

An excerpt from a detailed report by AWA Alexander Watson Associates

AWA has drafted a basic list of test methods for in-mold labels. It is not intended that the tests be strict and definitive, but they may be used as a basis for further adaptation and customization to build a full understanding of the critical parameters that companies are required to address when converting, supplying or using in-mold labels. In this excerpt, testing for surface tension of plastic films is discussed.

Surface tension of plastic films

Scope

This method covers measurement of the surface tension of plastic film surfaces in contact with drops of specific test fluids. Surface tension (wettability) of plastic films is one of the properties used to judge surface characteristics related to printability and adhesion of other coatings. Although the print key or adhesion property is not dependent on the surface tension only, this method often is used as a quick practical method. It is important to note that the determined wettability characterizes the immediate surface condition only, and that this condition can change during storage.

Definition

The surface tension is measured by applying a test fluid of known surface tension to the surface of the plastic film and recording the time taken for the continuous film of the fluid to break into droplets. The surface tension is defined as that level when a continuous film of the test fluid remains intact for two seconds. This test method is widely used across a variety of industries and is fully detailed as FINAT Test Method FTM15.

Test equipment

A range of test fluids and a stopwatch.

Test pieces

The test specimens must be at least 20x10mm taken with their length in the cross direction of the roll.

Test condition

23 degrees Celcius ± 2 degrees Celcius and 50 percent RH ± 5 percent RH. The test sample preferably should be conditioned for not less than four hours before testing, unless an immediate reading is required.

Test fluids

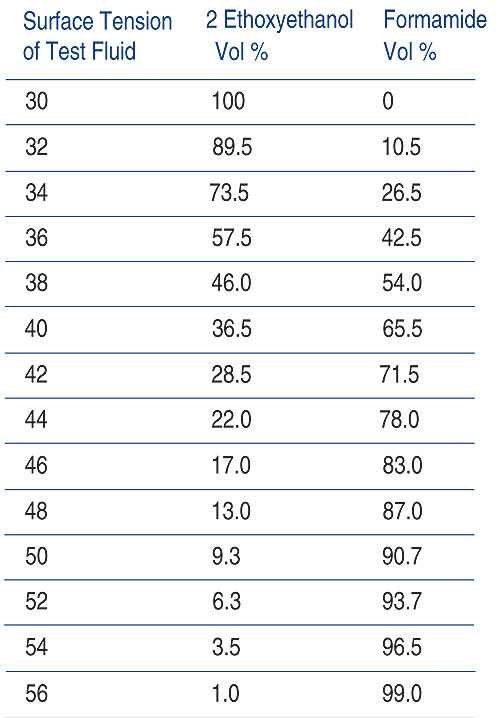

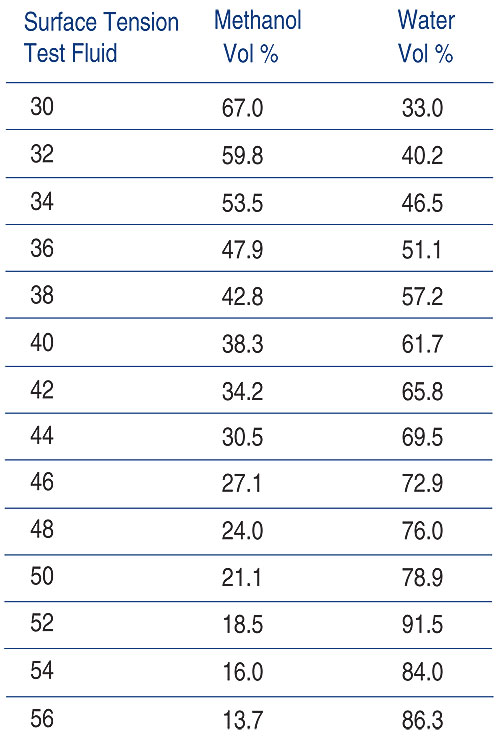

For polypropylene, polyester, PS and/or similar type of films, test fluids A (according to exhibit 2.2) are prepared by mixing Formamide (surface tension= 58 mN/m) and ethoxyethanol (surface tension 30 mN/m). These chemical raw materials may not be readily available. In that case, FINAT recommends the use of ready prepared solutions as listed at the end of this test method. Approximately 1 gram of a blue dye (e.g. Victoria Blue or Methylene Blue) is added to each liter of test fluid. For plastic films such as polyvinylchloride (PVC), which are affected (e.g. swelling) by the test fluids of series A, the test fluids B shown in exhibit 2.3 are prepared by mixing methanol (surface tension 73 mN/m). Approximately 1 gram of a red soluble dye (e.g. Fuchsine) is added to each liter of test fluid.

Procedure

Lay the specimen on a smooth flat surface. Spread the test fluid of known surface tension using a felt tip pen or soft brush lightly over an area of approximately 200x10mm of the test specimen. Note the time taken for the continuous film of the fluid to break into droplets. Breaking of the fluid into drops in less than two seconds, a lower numbered test fluid should be tried. Shrinkage of the liquid film on the sides of the applied fluid does not necessarily indicate a lack of wetting. The aim is to establish the lowest reading at an optimal dwell time of two seconds. Extreme care must be taken to ensure that the film surface is not touched or contaminated in the areas in which the tests are to be made as this will influence the test results.

Results

The lowest reading (surface tension) at an optimum dwell of two seconds is deemed equivalent to the surface tension of the test piece and is recorded in mN/m.